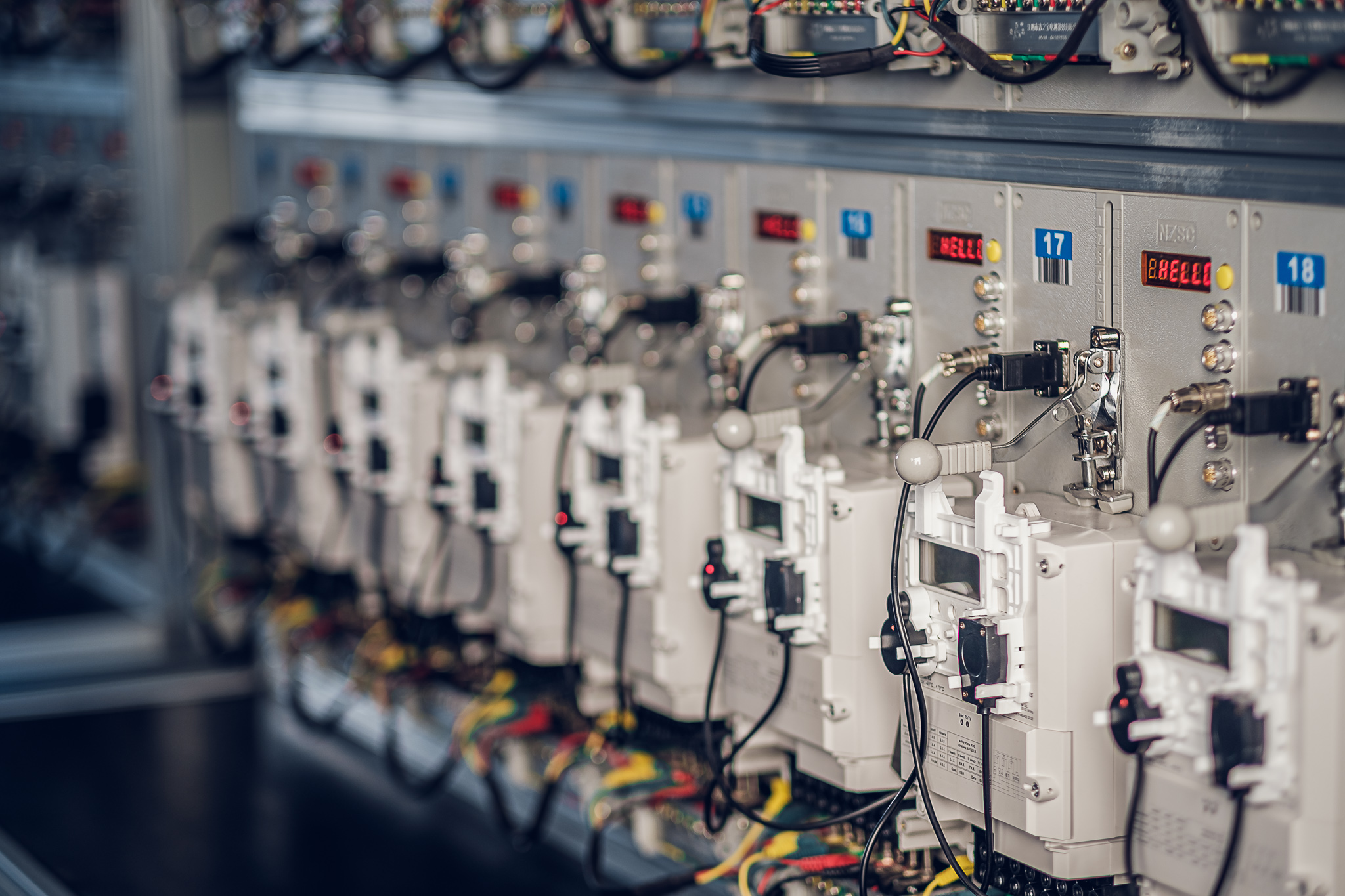

UAB 'ELGAMA-ELEKTRONIKA' is a partner company in FFR-2, specializing in the development and production of smart electricity meters. The company operates a fairly advanced CRM.

UAB 'ELGAMA-ELEKTRONIKA' is a partner company in FFR-2, specializing in the development and production of smart electricity meters. The company operates a fairly advanced CRM.

The range of used chemicals is not very big. One of the production steps, which requires chemicals, is assembly of printed circuit boards (PCBs). Major activities of company during the project concentrate namely on this step. The activities involve automation of conformal coating technology what opens an opportunity to substitute hazardous substances containing chemicals. The automation will also bring resource efficiency as well as quality control into the check.

To be more specific, for the longevity improvement of smart electricity meters, the company applies conformal coating to the printed circuit boards (PCBs) to create a protective film against moisture damage. While conformal coating adds value to the product and enhances its versatility in various moisture environments, the level of automation in the coating operation at the company is low, requiring some manual labor resulting in poorly controllable film thickness.

Consequently, this leads to the overuse of volatile organic compounds (VOC’s) containing reprotoxic conformal coating chemicals, posing risks to workers health and environment. To overcome these issue, conformal coating robot will be installed in the line to deliver multiple benefits for the company. The combined benefits include elimination of reprotoxic substance, reduction of conformal coating and solvent chemicals consumption, VOC emissions, personal protective equipment need, and hazardous solid waste generation.

Consequently, this leads to the overuse of volatile organic compounds (VOC’s) containing reprotoxic conformal coating chemicals, posing risks to workers health and environment. To overcome these issue, conformal coating robot will be installed in the line to deliver multiple benefits for the company. The combined benefits include elimination of reprotoxic substance, reduction of conformal coating and solvent chemicals consumption, VOC emissions, personal protective equipment need, and hazardous solid waste generation.

Also, the company will further improve chemical risk management elements by perfecting chemicals inventory and raising staff awareness about chemical hazard classes.