Substitution means the replacement or reduction of hazardous substances in products and processes by less hazardous or non-hazardous substances, or by achieving an equivalent functionality via technological or organisational measures.

Substitution

There are many reasons, why hazardous substances are substituted, such as:

- The use of a substance becomes legally prohibited

- Customers request that a particular substance is not used in a product any more

- Suppliers cease manufacture/import of a substance/mixture

- A substance may only be used if it is authorised

- Routine reformulation or re-design processes detect (financial, quality, technical) benefits of replacing a substance by another

- A company decides to improve its environmental performance in general (e.g. in the frame of implementing a standardised environmental management system) or

- A company decides to improve the environmental quality of (some of) its products, e.g. in order to meet requirements for an eco-label

Hazardous substances can be replaced by either one or several less hazardous substances or by changes in processes or product design or by organisational measures. Which of these options is feasible depends on many factors, including the substances’ use.

Why should hazardous substances be substituted?

Among the reasons could be, depending on the specific case:

- lower costs for the management of hazardous wastes

- lower costs for prevention measures to protect workers and less costs for environmental risk management and emissions

- lower risk of accidents and safety challenges in the company

- improved product quality with regard to the environmental and health performance

- better market position due to increased product performance regarding consumer health and the environment

- ensuring compliance with legal requirements (now and in the future) and simplifying documentation, reporting and/or monitoring requirements to the authorities

- substitution may enable new innovations and resource efficiency.

Which hazardous substances should be substituted (first)?

Highest priority for substitution should be given to substances of very high concern (SVHC) because they are deemed to pose unacceptable risks to human health and environment. These are substances with the following hazardous properties:

- carcinogenic, mutagenic or toxic for reproduction (CMR);

- persistent, bioaccumulative and toxic substances (PBT) and very persistent and very bioaccumulative substances (vPvB)

- other substances with similarly severe effects, such as endocrine disruptors, respiratory sensitisers and neurotoxic substances.

How to find out if there are hazardous substances which should be substituted in the company?

Substances of very high concern that are prioritised by legislation are listed on the so called REACH-candidate list. Substituting these substances is an advisable first step, also because these substances may become subject to authorisation and have to be identified if they are included in articles above a certain concentration. Compare the CAS/EC numbers of the substances used in the company with those listed in the candidate list for authorisation.

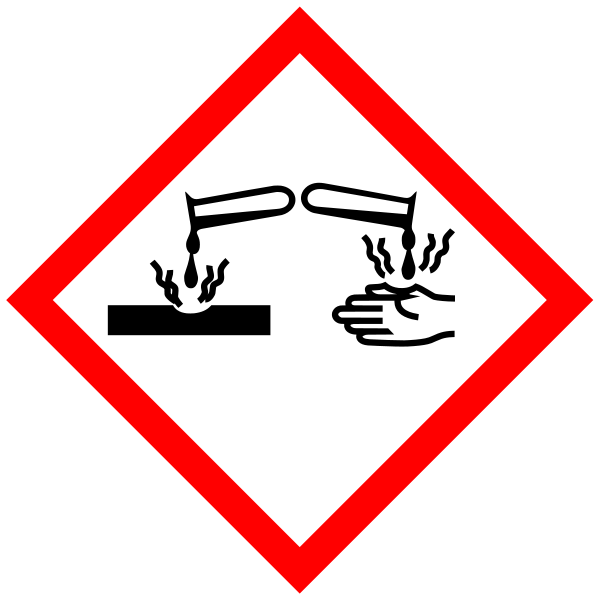

As a second step, further substances with undesirable hazards may be identified and substituted, such as those labelled with the following hazard pictograms:

If the employees complain about headaches, skin rashes, dizziness, nausea, eye irritation etc., this may be another important indication to check if substances that could cause such damage may be substituted.

If the following H-statements (330, 340, 350, 360, 370, 372, 410) are included in safety data sheet of substances or mixtures, this may also be an indication that substation would be useful.

Information about the hazardous properties of substances can be found in the following databases:

| Information on chemicals: ECHA website | Information about the chemical substances, which are produced in or imported into the European Union: data on hazardous properties, classification and labelling and safe use is available here. |

| Classification and labelling information provided by manufacturers and importers for substances on the EU market, also if not registered. | |

| OECD eChemPortal | International data from various sources on substance hazards. |

How to prioritize substances which are to be substituted?

Apart from the hazardous properties, other criteria may support the decision making on which substances to substitute (first) such as:

- (future) laws (the substance will be banned or restricted)

| Substances already banned or restricted | |

| Substances requiring authorisation | |

| Substances which are likely to be subject to authorisation or restriction in the future | ChemSec Sin List |

- occupational health and safety issues (staff reviews, the working environment risk assessment results);

- considerable cost in reducing emissions into the environment, the emission thresholds;

- customer pressure;

- product and process changes that may take place simultaneously with the chemical substitution;

- company's policy for the phase-out of hazardous substances.

What are the main steps in substitution process?

Substitution can be done in different ways, depending on the use of hazardous chemicals. However, in order to assess all possible aspects of substitution, it is recommended to apply the following steps:

- Identification of hazards and risks from the use of a substance (status quo), including description of challenges in the handling and use of it e.g. by workers, in storage and in the final product

- Identification of possible alternatives, including process and product changes or organisational measures; this implies considering the functionality a substance fulfils in the alternatives identification rather than to focus on a “simple replacement”

- Assessment alternatives, i.e. identification of risks from the use of an alternative, challenges for practical handling and use; selection of the most promising options;

- Analysis of other consequences that would result from the use of these alternatives, including costs, workers protection, use of machines etc.;

- Comparison of alternatives, including with the current situation and regarding the costs and benefits of using the current substance and implementing the solution;

- Testing of the actual feasibility of the alternative in small scale production

- Upscaling of tests to “normal conditions”

- Decision making on the substitution;

- Full implementation of substitution.