Substitution means the replacement or reduction of hazardous substances in products and processes by less hazardous or non-hazardous substances, or by achieving an equivalent functionality via technological or organisational measures.

Substitution

Substitution may be defined as: “the replacement or reduction of hazardous substances in products and processes by less hazardous or non-hazardous substances, or achieving an equivalent functionality via technological or organisational measures” (Lissner and Lohse, 2003). A key term within substitution is chemical or technical function, which refers to the function of the substance in the material, product or process. Defining the substance’s function in a specific application usually makes it easier to identify viable alternatives.

There are many reasons, why hazardous substances are substituted, such as:

- The substance has been restricted or banned under regulatory frameworks such as REACH or national legislation.

- Customers, downstream users, or markets (e.g. green public procurement) demand the removal of specific hazardous substances.

- Suppliers cease manufacture/import of a substance or mixture.

- The substance requires authorisation under REACH, and the company does not wish to apply or bear the associated costs.

- Routine reformulation or redesign efforts reveal economic, technical, or quality advantages in replacing a hazardous substance.

- The company aims to improve its environmental or occupational health performance, e.g. by implementing ISO 14001 or EMAS.

- A company decides to improve the environmental quality of (some of) its products, e.g. in order to meet requirements for an eco-label.

Substitution is not always a one-to-one replacement. Alternatives may include using one or more less hazardous substances, implementing changes in production processes, redesigning the product, or introducing organisational or protective measures. The feasibility of each option depends on the specific use and function of the substance in question.

Why should hazardous substances be substituted?

Depending on the specific context, substitution of hazardous substances can offer multiple advantages, such as:

- reduced costs for the management of hazardous wastes,

- reduced costs for occupational safety measures and environmental risk management and emissions,

- reduce risk of accidents and safety challenges in the company,

- improved product quality with regard to the environmental and health performance,

- enhanced market competitiveness through greener products,

- ensuring compliance with current and anticipated regulatory requirements and simplifying documentation, reporting and/or monitoring requirements to the authorities,

- opportunities for innovation, improved resource efficiency, and circular economy compatibility.

Which hazardous substances should be substituted (first)?

Priority should be given to substituting substances of very high concern (SVHCs), as defined under Article 57 of REACH. These substances are considered to pose unacceptable risks to human health or the environment and may include:

- carcinogenic, mutagenic or toxic for reproduction (CMR, categories 1A/1B);

- persistent, bioaccumulative and toxic substances (PBT) and very persistent and very bioaccumulative substances (vPvB);

- other substances with similarly severe effects, such as endocrine disruptors, respiratory sensitisers and neurotoxic substances.

How to find out if there are hazardous substances which should be substituted in the company?

Substances of very high concern that are prioritised by legislation are listed on the so called REACH-candidate list. Substituting these substances is an advisable first step, also because these substances may become subject to authorisation and have to be identified if they are included in articles above a certain concentration. Compare the CAS/EC numbers of the substances used in the company with those listed in the candidate list for authorisation.

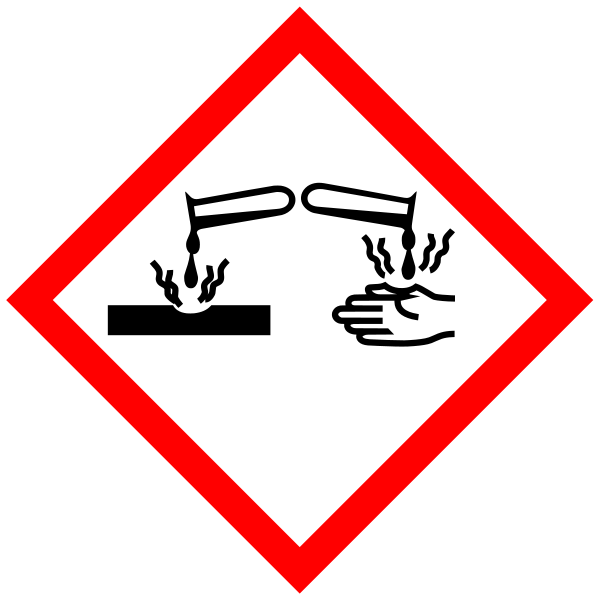

As a second step, identify other hazardous substances by checking for hazard pictograms and H-statements on the label or Safety Data Sheet (SDS):

Pay particular attention to H-statements such as H330, H340, H350, H360, H370, H372, H410, which signal serious health or environmental risks.

If the employees complain about headaches, skin rashes, dizziness, nausea, eye irritation etc., this may be another important indication to check if substances that could cause such damage may be substituted.

Review the results of workplace exposure measurements and risk assessments.

Information sources on the hazardous properties of substances:

| ECHA Information on Chemicals | Information about the chemical substances, which are produced in or imported into the European Union: data on hazardous properties, classification and labelling and safe use is available here. |

| ECHA Classification & Labelling Inventory | Classification and labelling information provided by manufacturers and importers for substances on the EU market, also if not registered. |

| OECD eChemPortal | Access to international databases providing substance hazard information. |

How to prioritize substances which are to be substituted?

Apart from the hazardous properties, other criteria may support the decision making on which substances to substitute (first) such as:

- Legal obligations: Substances already restricted, or expected to be restricted or require authorisation under REACH:

| Substances already banned or restricted | Substances restricted under REACH |

| Substances requiring authorisation | Authorisation List |

| Substances which are likely to be subject to authorisation or restriction in the future | ChemSec Sin List |

- occupational health and safety issues (staff reviews, the working environment risk assessment results);

- considerable cost in reducing emissions into the environment, the emission thresholds;

- market or customer demands for cleaner alternatives;

- product and process changes that may take place simultaneously with the chemical substitution;

- corporate sustainability goals or chemical phase-out strategies.

What are the main steps in substitution process?

A structured approach to substitution ensures that all relevant factors are considered. The following steps are recommended:

- Assess the current situation: Identify the hazards and risks associated with the substance in its current use. Consider all relevant aspects, including worker exposure during handling, risks during storage, emissions or waste during processing, and any residual presence in the final product.

- Identify alternatives: Consider not only direct substance replacements but also changes in product design, processes, or organisational practices.

- Evaluate alternatives: Assess each potential substitute in terms of its hazardous properties, technical feasibility, performance, and associated risks. This includes identifying potential health, safety, and environmental hazards, as well as practical challenges related to handling, storage, or implementation. Based on this evaluation, select the most promising and viable alternatives for further testing or analysis

- Consider broader impacts: Include cost analysis, worker safety, machine compatibility, training needs, etc.

- Compare with the current solution: Weigh the benefits and drawbacks, including lifecycle and cost implications.

- Pilot testing: Assess the actual feasibility of the selected alternative under small-scale conditions.

- Scale-up: Conduct trials under normal operational conditions.

- Decision-making: Choose the most suitable option based on the evidence gathered.

- Full implementation: Integrate the substitution into routine operations, with appropriate communication and training.

Avoid regrettable substitution! Regrettable substitution occurs when a hazardous chemical is replaced with an alternative that appears safer but later turns out to be equally or even more harmful to human health or the environment.

Further information on chemical substitution can be found at the following sources:

https://echa.europa.eu/how-to-substitute

https://www.kemi.se/en/guidance-for-companies/substitution-of-hazardous-substances